In recent years, 3D printing technology has revolutionized the fields of medicine and healthcare, offering endless possibilities and advancements. From customized prosthetics to surgical planning and even bioprinting organ tissue, 3D printing has opened up a new realm of possibilities in the medical industry. This blog explores the wide range of applications and advancements in 3D printing in healthcare, as well as the challenges and regulations that come with this innovative technology. Join us as we uncover the revolutionary impact of 3D printing in medicine and healthcare.

The Role of 3D Printing in Surgical Planning

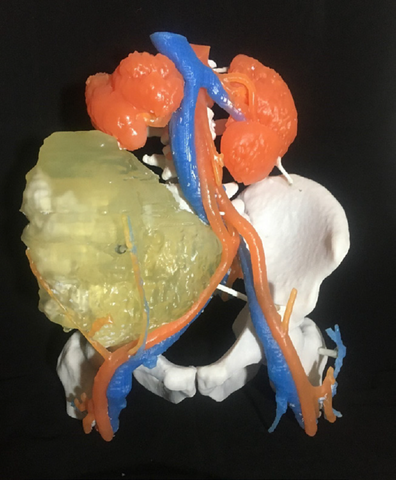

One of the most significant impacts of 3D printing in medicine and healthcare is its role in surgical planning. Traditional surgical procedures often involve inherent risks and uncertainties that can prolong patient recovery time and increase the chances of complications. However, with the advent of 3D printing, surgeons now have access to detailed and accurate anatomical models that can be created from patient-specific imaging data.

These 3D-printed models allow surgeons to visualize and plan complex surgical procedures with more precision and clarity than ever before. By examining these tangible replicas of patients' anatomy, surgeons can identify potential challenges and develop personalized surgical strategies. This innovative approach not only improves surgical outcomes but also reduces operating time, minimizes complications, and enhances patient recovery.

Moreover, 3D printing enables surgeons to simulate and practice surgeries before the actual procedure takes place. This virtual experience allows surgeons to refine their techniques, troubleshoot potential problems, and increase their confidence in executing successful surgeries. Consequently, 3D printing empowers surgeons to provide safer and more effective treatments to their patients.

Precision and Customization: 3D Printing's Impact on Medical Devices

In addition to its role in surgical planning, 3D printing is revolutionizing the field of medical devices, providing unprecedented precision and customization. Traditional manufacturing techniques often involve mass production of standardized medical devices, which may not always meet the specific needs of individual patients. However, with the advent of 3D printing, medical devices can now be customized to fit a patient's unique anatomical requirements.

For instance, prosthetics and orthotics, which traditionally required extensive manual adjustments, can now be created using 3D printing technology. This allows for more precise and comfortable fitting, enhancing patient mobility and quality of life. Additionally, 3D printing enables intricate designs and complex structures to be created, offering greater functionality and comfort for patients.

Furthermore, the customization possibilities offered by 3D printing extend to other medical devices such as implants and dental appliances. By using patient-specific imaging data, 3D printers can produce implants that seamlessly integrate with the patient's anatomy, improving surgical outcomes and reducing the risk of complications.

The precision and customization capabilities of 3D printing are transforming the medical device industry, making it possible to provide patients with tailored solutions that address their unique needs.

The Future of Organ and Tissue Printing: Advancements and Challenges in 3D Technology

While 3D printing has already made significant strides in the field of medical devices, its potential impact on organ and tissue printing is truly groundbreaking. The ability to create functional organs and tissues using 3D printing technology has the potential to revolutionize treatments for conditions such as organ failure and tissue damage.

Researchers have already demonstrated the feasibility of 3D printing organs and tissues using a variety of biocompatible materials and bioinks. By layering these materials, 3D printers can create complex structures that mimic the native architecture of organs and tissues. This opens up new possibilities for organ transplantation, as patient-specific organs can be printed using a patient's own cells, eliminating the need for donor organs and the risk of rejection.

However, there are still significant challenges to overcome before 3D-printed organs and tissues become a widespread reality. One major challenge is the development of suitable bioinks that can support cell growth and function. Additionally, ensuring the functional integration of 3D-printed organs into the recipient's body is another hurdle that researchers need to address.

Despite these challenges, the potential benefits of 3D-printed organs and tissues are undeniable. Patients in need of organ transplants could avoid long waiting lists and the risk of organ rejection, leading to improved patient outcomes and quality of life.

3D printing is poised to revolutionize the medical field, offering unprecedented precision, customization, and now the potential to print functional organs and tissues. By addressing the challenges and continuing to innovate, researchers and medical professionals can unlock the full potential of 3D printing in medicine and healthcare, providing patients with innovative and personalized solutions that were once unimaginable.

Innovations in Pharmaceutical Applications through 3D Printing

In addition to its potential impact on organ and tissue printing, 3D printing is also revolutionizing pharmaceutical applications in medicine and healthcare. 3D printing has opened new possibilities for the production of personalized medicine, allowing for precise dosage and drug delivery systems tailored to individual patients.

First 3D Printed Drug - FDA Approved.

One of the most notable advancements in pharmaceutical applications is the development of 3D-printed tablets. Traditional tablets often have a one-size-fits-all approach, which may not be suitable for all patients. With 3D printing, tablets can be produced with specific dosages and combinations of active ingredients, enabling personalized medicine. This technology also allows for the customization of drug release profiles, ensuring optimal therapeutic outcomes.

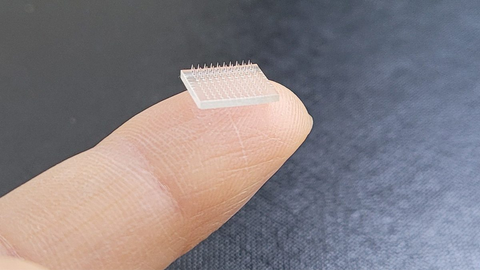

Furthermore, 3D printing is being utilized to create complex drug delivery systems, such as implants and microneedle arrays. These innovative devices can be precisely fabricated to deliver drugs to specific locations in the body, enhancing treatment efficacy and patient comfort.

3D Printed Vaccine Patch

The use of 3D printing in pharmaceutical applications is still in its early stages, but the potential benefits are vast. This technology has the potential to transform drug manufacturing and improve patient outcomes by providing tailored and more effective treatments. The future of pharmaceuticals is being shaped by the revolutionary capabilities of 3D printing.

Environmental Impacts and Sustainability of 3D Printing in Healthcare

As we continue to delve into the revolutionary impact of 3D printing in medicine and healthcare, it is essential to consider the environmental implications of this groundbreaking technology. While 3D printing offers numerous benefits in terms of customization and efficiency, it is also crucial to analyse its sustainability and potential impact on the environment.

One of the significant advantages of 3D printing in healthcare is the reduction of waste. Traditional manufacturing processes often result in unnecessary material wastage, making it challenging to optimize resources and reduce environmental harm. With 3D printing, however, the ability to produce intricate structures and precise shapes reduces the need for excess materials, resulting in less waste generation.

Moreover, 3D printing allows for a streamlined supply chain, reducing transportation requirements, and mitigating the carbon footprint associated with traditional manufacturing. By producing medical devices, implants, and pharmaceuticals on-site or locally, healthcare facilities can minimize their impact on the environment while also ensuring a more efficient and cost-effective process.

In terms of energy consumption, 3D printing does utilize electricity and various raw materials. However, when compared to conventional manufacturing methods, the overall energy consumption of 3D printing can be significantly lower. This lower energy consumption, coupled with the ability to use biodegradable and recyclable materials in the printing process, contributes to a more sustainable healthcare system.

Despite these positive aspects, it is important to acknowledge that 3D printing technology is not entirely eco-friendly. The disposal of used or failed prints can still pose environmental challenges if not properly managed. Therefore, ongoing research and development are necessary to address these concerns and further enhance the sustainability of 3D printing in healthcare.

In the upcoming blog section, we will explore the efforts being made to mitigate the environmental impacts of 3D printing in healthcare. From advancements in bio-based and biodegradable materials to recycling initiatives and waste management strategies, we will delve into the innovative solutions that are shaping a more sustainable future for this remarkable technology.

Regulatory Perspectives: FDA's Approach to 3D-Printed Medical Devices and Products

In the ever-evolving landscape of medical technology, it is crucial to address the regulatory considerations surrounding 3D printing in healthcare. As the use of this technology becomes more widespread, it is imperative to ensure that patient safety and product effectiveness are not compromised.

The U.S. Food and Drug Administration (FDA) plays a pivotal role in assessing and approving medical devices and products, including those produced through 3D printing. The FDA's approach to regulating this innovative technology revolves around ensuring that 3D-printed medical devices and products meet the same safety and efficacy standards as their traditionally manufactured counterparts.

The FDA evaluates 3D-printed medical devices and products based on their intended use, design, materials used, and manufacturing processes. Additionally, they assess factors such as biocompatibility, sterility, and durability.

To ensure proper oversight, the FDA has released specific guidance for industry stakeholders regarding the use of 3D printing in healthcare. This guidance encourages a collaborative approach between manufacturers and regulatory authorities, facilitating a greater understanding of the technology's unique challenges and opportunities.

Revolutionizing Prosthetics: The Impact of 3D Printing on Cost, Accessibility, and Customization

In addition to its impact on medical devices and products, 3D printing is revolutionizing the field of prosthetics. Traditional prosthetics can be expensive and often require lengthy and complex manufacturing processes. However, 3D printing has the potential to significantly reduce costs, increase accessibility, and enhance customization for prosthetic limbs.

With 3D printing, prosthetics can be created using digital scans of an individual's residual limb, ensuring a perfect fit. This customization allows for better comfort, functionality, and a higher quality of life for prosthetic users. Furthermore, 3D printing enables the production of prosthetics at a fraction of the cost and time compared to traditional methods.

The accessibility of 3D printing also extends to developing countries or areas with limited access to prosthetic services. The technology allows for the creation of prosthetics on-site, eliminating the need for expensive transportation and logistical challenges.

Moreover, the iterative nature of 3D printing allows for continuous improvements and modifications to prosthetic designs. This flexibility enables prosthetic specialists to meet the individual needs and evolving requirements of patients.

FAQ’s

Q1: How does 3D printing enhance the customization of prosthetics in healthcare?

A1: 3D printing allows for the creation of prosthetics using digital scans of an individual's residual limb, ensuring a perfect fit and greater comfort, functionality, and quality of life for prosthetic users.

Q2: What role does 3D printing play in improving surgical outcomes?

A2: 3D printing enables surgeons to create detailed and accurate anatomical models from patient-specific imaging data, allowing for more precise and efficient surgical planning, reduced operating time, and minimized complications.

Q3: In what ways is 3D printing transforming the production of medical devices?

A3: 3D printing brings unprecedented precision and customization to medical devices, allowing for the creation of implants, prosthetics, and orthotics tailored to individual patient needs, thus enhancing functionality and patient comfort.

Q4: What are the potential impacts and challenges of 3D printing in organ and tissue printing?

A4: 3D printing has the potential to revolutionize organ transplantation by creating patient-specific organs and tissues, reducing the need for donor organs and risk of rejection. However, challenges include developing suitable bioinks and ensuring functional integration with the patient's body.

Q5: How is 3D printing influencing pharmaceutical applications?

A5: 3D printing allows for the production of personalized medicine with specific dosages and drug delivery systems tailored to individual patients. This includes 3D-printed tablets with customized dosages and drug release profiles.

——————————————————