As 3D printing continues to gain popularity, choosing the right filament for your project is crucial. Two of the most used filaments are PETG and PLA, each with its own unique properties and strengths. PETG is known for its durability and chemical resistance, while PLA is praised for its ease of use and biodegradability. But which filament holds the most strength?

Understanding the differences between PETG and PLA

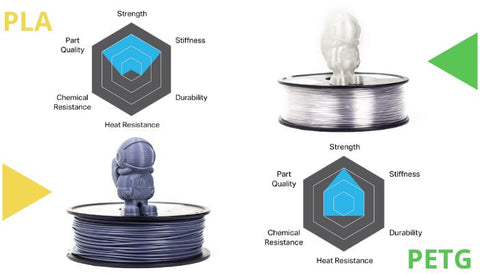

PETG, short for polyethylene terephthalate glycol-modified, is a thermoplastic polyester that offers excellent durability and toughness. It is known for its high impact strength, making it suitable for applications that require resistance to mechanical stress or exposure to chemicals. PETG is also highly resistant to moisture and weathering, making it a popular choice for outdoor applications.

On the other hand, PLA, or polylactic acid, is a biodegradable thermoplastic derived from renewable sources such as corn starch or sugarcane. PLA is easy to print with and offers good dimensional accuracy and stability. However, it is less durable than PETG and more prone to deformation under stress or high temperatures.

Strength comparisons and considerations

Tensile strength refers to a material's ability to withstand pulling or stretching forces without breaking. PETG is known for its high tensile strength, making it suitable for applications that require structural integrity and durability. PLA, on the other hand, has a lower tensile strength, which means it may not hold up as well under high stress or heavy loads.

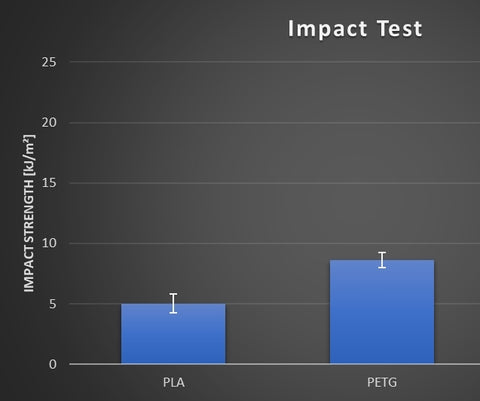

When it comes to impact resistance, PETG outperforms PLA. PETG can withstand impacts and sudden forces without cracking or breaking, making it an excellent choice for parts that may undergo rough handling or accidental drops. PLA, while biodegradable and easy to print with, is more prone to deformation or fracturing under impact.

Consider your project's requirements for strength and durability when choosing between PETG and PLA. If you need a filament that can handle heavy loads and impact, PETG may be the better option. However, if your project is less demanding in terms of strength and you value biodegradability, PLA could be a suitable choice.

What is the difference between PET and PETG plastic?

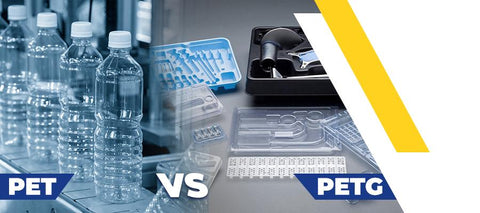

While discussing the comparative analysis of PETG and PLA, it is essential to clarify the difference between PET and PETG plastic. PET, which stands for Polyethylene Terephthalate, and PETG, which stands for Glycol-Modified Polyethylene Terephthalate, are both thermoplastic polymers widely used in various applications.

The primary distinction between PET and PETG lies in their chemical composition. PET is a rigid, clear, and highly solvent-resistant material commonly used in beverage bottles and food packaging. On the other hand, PETG is a modified version of PET, with the addition of glycol, which enhances its flexibility and impact resistance.

Due to its flexibility and impact resistance, PETG is often preferred for applications where durability and toughness are paramount, such as 3D printing, medical devices, signage, and protective packaging. PET, on the other hand, is valued for its rigid structure and crystal-clear transparency, making it suitable for products that require high clarity, such as water bottles and food containers.

Application and versatility of PETG and PLA

Both PETG and PLA have a wide range of applications, but their strengths lie in different areas. PETG, with its flexibility and impact resistance, is highly suitable for 3D printing, medical devices, signage, and protective packaging. Its ability to withstand rough handling and potential impacts makes it an excellent choice for applications where durability is paramount. Additionally, its transparency adds to its appeal for certain projects where visual clarity is important.

On the other hand, PLA offers its own set of advantages. PLA is biodegradable, derived from renewable resources, and has a lower carbon footprint compared to other plastics. It is commonly used in food packaging, disposable cutlery, and various consumer products. Its biodegradability makes it an environmentally friendly option, especially for projects that prioritize sustainability.

When considering the application of PETG or PLA, it is crucial to analyze the specific requirements of your project. Factors such as the need for flexibility, impact resistance, transparency, or biodegradability will play a vital role in determining which material is the right fit.

Is PETG plastic BPA free?

Bisphenol A, commonly known as BPA, is a chemical compound found in many types of plastics. It has raised concerns regarding its potential health effects, particularly in relation to hormone disruption. Therefore, it is essential to understand whether PETG plastic, one of the materials under analysis, is BPA free.

Unlike certain types of plastic, such as polycarbonate, which may contain BPA, PETG is considered BPA free. PETG is composed of PET (polyethylene terephthalate) and glycol, which are not known to exhibit similar health concerns as BPA. As a result, PETG can be considered a safer alternative when it comes to plastic materials.

It should be noted, however, that while PETG may be free from BPA, it is always recommended to verify the specific product or manufacturer's declaration to ensure that the materials used meet your desired safety standards.

What are the disadvantages of PETG?

While PETG offers numerous advantages in terms of its strength, durability, and transparency, it does have a few drawbacks to consider. One of the main disadvantages of PETG is its susceptibility to scratching. Compared to other plastics, PETG is more prone to developing surface marks and scuffs. This can be particularly noticeable in high-wear applications, such as protective covers or displays.

Additionally, PETG has a lower heat resistance compared to other materials like PLA. It tends to soften at higher temperatures, which can limit its use in applications requiring prolonged exposure to elevated temperatures.

Another important consideration is PETG's tendency to absorb moisture. If exposed to humid environments, PETG may absorb water molecules, leading to reduced mechanical properties and potential issues with dimensional stability.

Conclusion: choosing the right filament for your project

In conclusion, deciding between PETG and PLA ultimately depends on the specific requirements of your project. While PETG offers impressive strength and durability, it is more prone to scratching and has lower heat resistance. On the other hand, PLA is less susceptible to scratching and has better heat resistance, but it is not as strong as PETG.

Consider the application of your project and the environmental factors it will be exposed to. If you require a material that can withstand high wear or prolonged exposure to elevated temperatures, PETG might be the better choice. However, if scratch resistance and heat resistance are less critical, PLA could be a suitable option.

Ultimately, it is important to evaluate the strengths and weaknesses of each material and make an informed decision based on your project's specific needs. The final section of this blog series will provide a comprehensive comparison between PETG and PLA, making it easier for you to choose the right filament for your next 3D printing endeavor.

FAQS

Q1: What are PLA and PETG filaments, and how do they differ?

A: PLA (Polylactic Acid) and PETG (Polyethylene Terephthalate Glycol) are two commonly used 3D printing filaments. PLA is a biodegradable thermoplastic made from renewable resources like cornstarch, while PETG is a thermoplastic polyester. The main difference is that PETG is more durable and flexible than PLA, which is stiffer but easier to print with.

Q2: Which filament is easier to print with, PLA or PETG?

A: PLA is generally easier to print with, especially for beginners. It has a lower printing temperature and adheres well to the print bed, reducing the chances of warping or adhesion issues. PETG, on the other hand, requires higher temperatures and may be more prone to issues like stringing and bed adhesion problems.

Q3: What are the key properties of PLA and PETG filaments?

A: PLA is known for its biodegradability, ease of printing, and vibrant colors. It's often used for decorative and prototype prints. PETG offers excellent layer adhesion, impact resistance, and durability, making it suitable for functional parts, mechanical components, and objects that need to withstand some wear and tear.

Q4: When should I choose PLA over PETG or vice versa for my 3D printing project?

A: Choose PLA if you prioritize ease of use, biodegradability, and a glossy finish for non-functional items. Opt for PETG when you need stronger, more durable parts with good layer adhesion, or if your project requires parts to be exposed to higher temperatures. Consider the specific requirements of your 3D printing project and the material properties that best match those needs when deciding between PLA and PETG.

——————————————————